Retrofit of an Automated Plant for the Production of Filigree Concrete Slabs - 2019

For 25 years, customers have benefited from our industry expertise

- Increasing the efficiency of existing systems

- Equipping new investments

- Integration with ERP systems

- Digitalization of the production process

Robotics

We currently use Simatic S7-1500 controllers with integrated safety functionality and ProfiNET as the fieldbus system.

This provides the necessary flexibility to meet increasingly complex safety requirements. The powerful fieldbus system also offers optimal integration options with KUKA robots.

We now offer new solutions with Kuka mxAutomation for the complete integration of the robot program into a Siemens PLC. This means that only the PLC programmer is needed for commissioning and service.

Engineering

Through company-wide standardization of software and the use of established function libraries, we reduce our engineering time and costs.

We gladly avoid surprises during commissioning. A high level of planning depth enables a short downtime, especially for retrofits and modernizations.

Despite careful planning, unforeseen events can occur. Our experienced engineers and technicians will support you with their skills and expertise.

The Human at the Center

A machine is always operated by a human. We don’t just pull the operating concept for your system out of a drawer. It is tailored to your needs in collaboration with your specialists and adapted to your working environment. We offer everything from machine-level control panels to mobile handheld devices and complex control room applications. Good usability is a hallmark of quality for us. We are happy to advise you.

Special Applications

New production processes, new technologies – nothing is as constant as change. In developing a wide variety of applications, we have gained extensive experience and expertise over the years. This enables us to solve your specific challenges as well. Among other things, we rely on the following for the implementation of our projects:

- Laser marking for permanent component labeling

- RFID systems for effective product tracking

- 2D, 3D, and code cameras for detecting, evaluating, and identifying components and their features

- Integration of new manufacturing processes into the production workflow (3D printing, robot-assisted gravity die casting)

Digitalization in Manufacturing

Increasingly demanding requirements continuously drive the need for greater flexibility in your production.

A higher degree of digitalization in your systems offers many advantages for you.

We have developed a customized solution for our customer that is based on a central database, covering everything from production planning to machine and production data. Operation is fully web-based – from production preparation, parameter management, and production data collection to order management, all the way down to the core shooting machine.

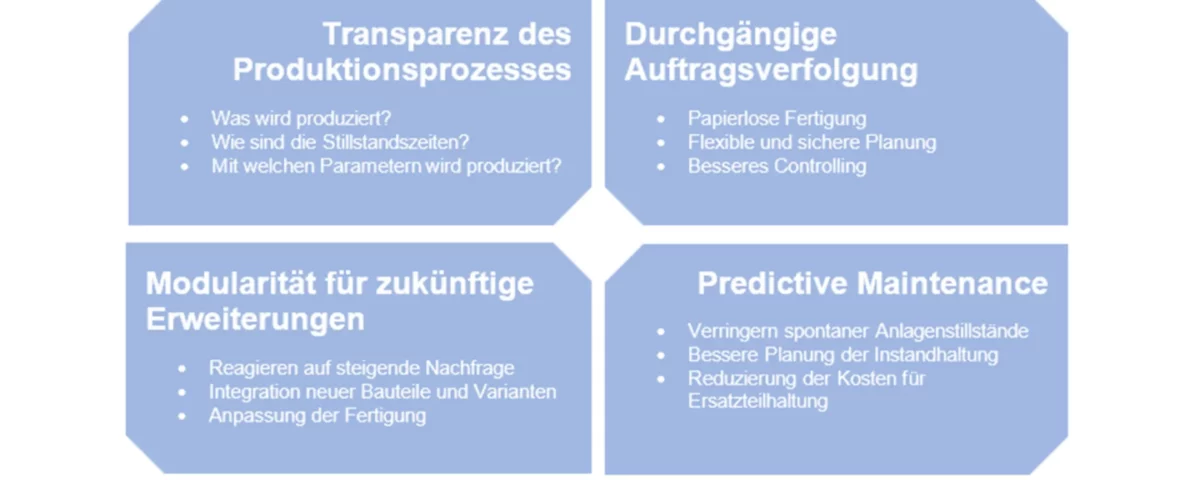

Transparency of the Production Process

- What is being produced?

- What are the downtime periods?

- With which parameters is production taking place?

End-to-End Order Tracking

- Paperless manufacturing

- Flexible and secure planning

- Improved controlling

Modularity for Future Expansions

- Responding to increasing demand

- Integration of new components and variants

- Adaptation of production

Predictive Maintenance

- Reducing unexpected plant downtimes

- Better maintenance planning

- Reducing spare parts inventory costs