Retrofit of an Automated System for the Production of Filigree Concrete Precast Slabs - 2019

Task Description

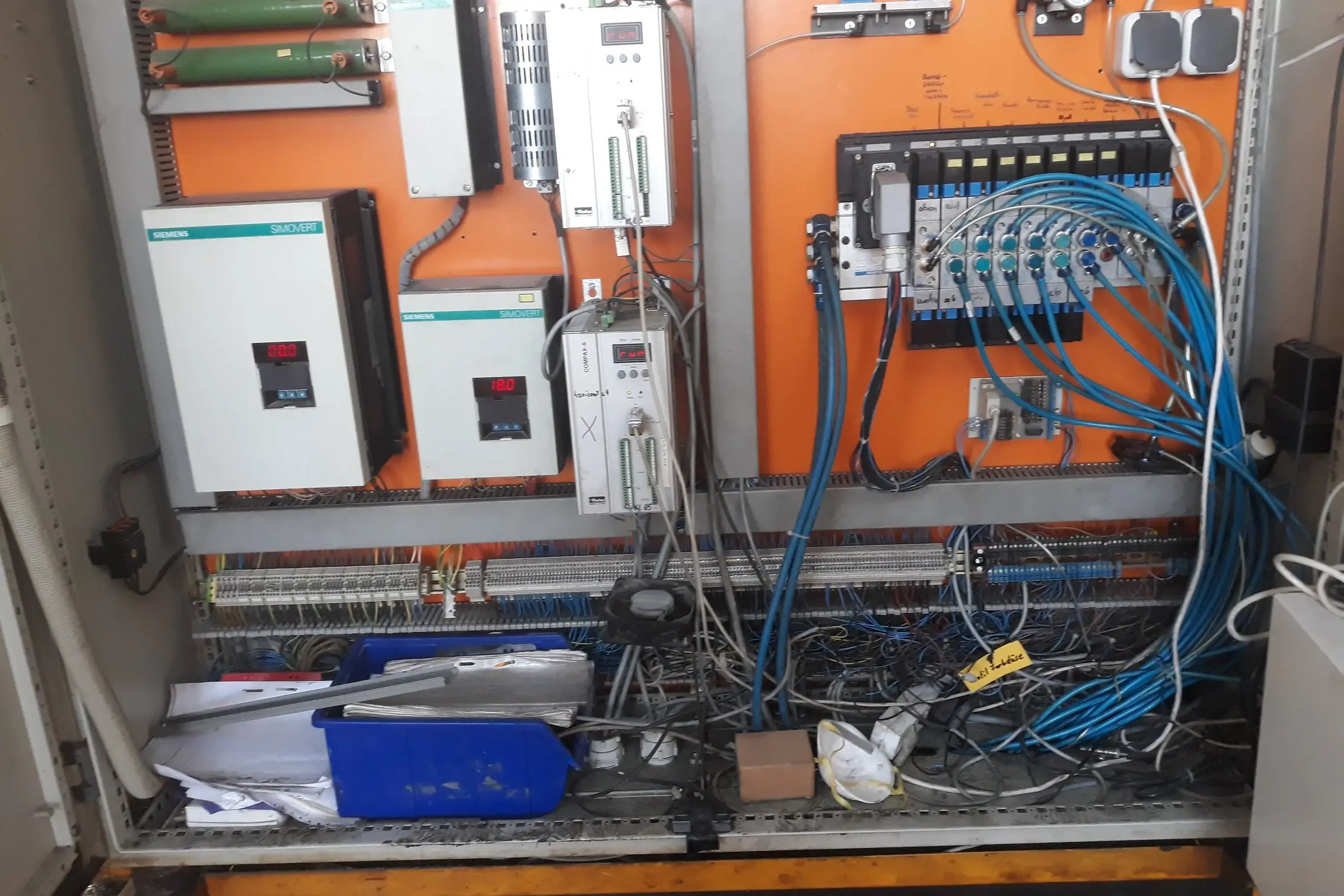

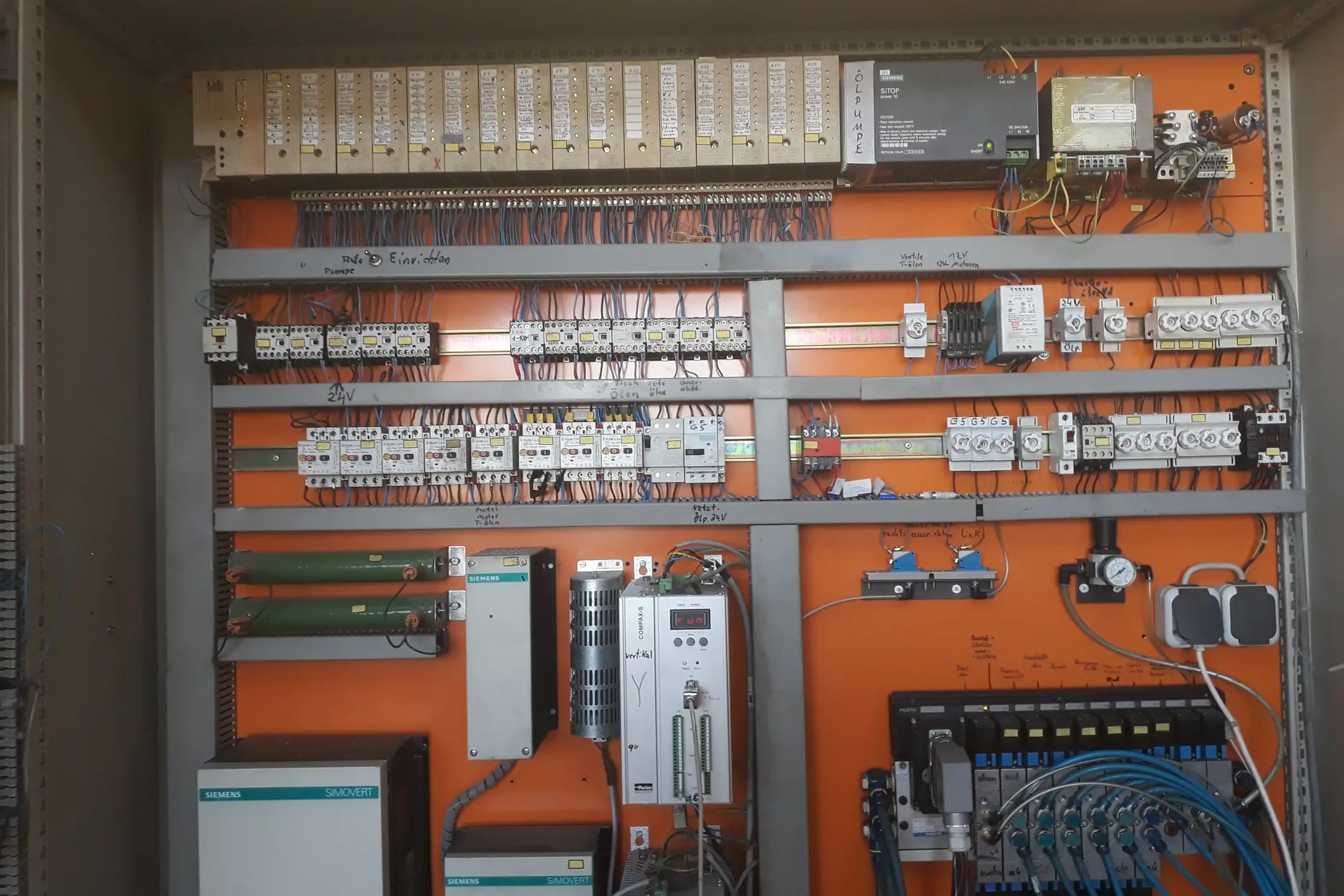

After twenty years of operation, the operator decided to completely modernize the existing control system. On the one hand, the four S5 controllers in use (S5 95U and S5 115U) were to be replaced; on the other hand, there were still special solutions in place in the form of custom-built electronic systems for position detection and weight measurement.

The servo amplifiers in use were also to be replaced during this process.

The remaining switchgear technology was to be retained for cost reasons.

Solution Approach

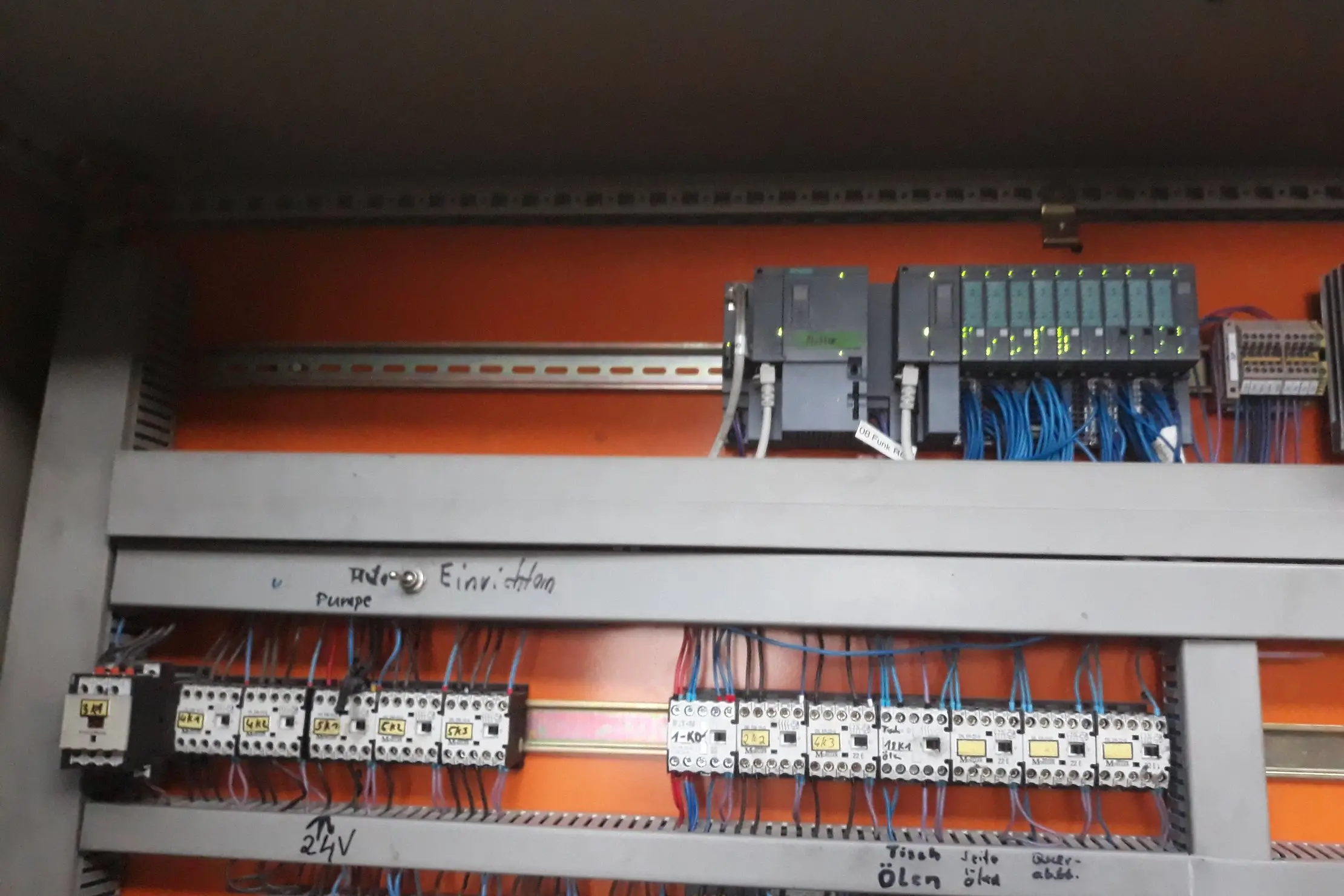

The Simatic S5 controllers are replaced with TIA 1512 CPUs. All systems are equipped with operator panels for visualization, operation, and parameter management. All proprietary electronic solutions are replaced with standardized industrial components. Siwarex is used for the weighing system, and the position measurements are replaced by modern absolute encoders with Profinet.

The drive amplifiers for the Parker servo drives are replaced with Sinamics S110. The Parker servo motors remain in operation.

The control program is completely redeveloped. On the one hand, it is not practical to migrate old S5 control programs (as the software architecture has fundamentally changed), and on the other hand, various minor deficiencies should be corrected during this process.

A switchover period of four weeks at the beginning of the year, during the low-demand construction period, was available for the conversion.

This schedule was met by us.

The conversion of the switchgear with our own personnel took only two days. After an additional three days, the I/O test was completed.

Only the commissioning of the Parker servo motors with the Sinamics S110 turned out to be more complex, but it was also successfully resolved.

The remaining time was used for cold commissioning and functional testing together with the operator.

The start-up of production was accompanied for a period of two weeks.